Glassblower hopes to pass down skills of traditional craft

Updated: 2024-12-06

Handmade process produces unique and delicate designs

Luo Qinqin works at the factory of Shanxi Dahua Glass Industrial Co in Qixian county, Shanxi province. ZHU XINGXIN/CHINA DAILY

Three hundred years ago, merchants from Shanxi province exported tea to foreign countries on the Eurasian continent, and in turn they brought back the secrets of glassware manufacturing.

Luo Qinqin, a 40-year-old native of Qixian county in Shanxi, is a skilled glassworker at Shanxi Dahua Glass Industrial Co. She is one of the few female artisans who have mastered the craft of glass pulling.

"I treat each of my products like my own children," she said.

In a workshop in Qixian, where glassware is handmade with the aid of blowpipes, Luo and her colleagues are busy fulfilling overseas orders.

The workshop's primary heat source is the furnace, where the molten glass is heated to 1,500 C.

Every day, Luo works in extreme heat, with the workshop temperature exceeding 40 C, often soaking her clothes with sweat. Despite this, she must push and pull a 1.5 meter, 1 kilogram blowpipe 5,000 to 6,000 times.

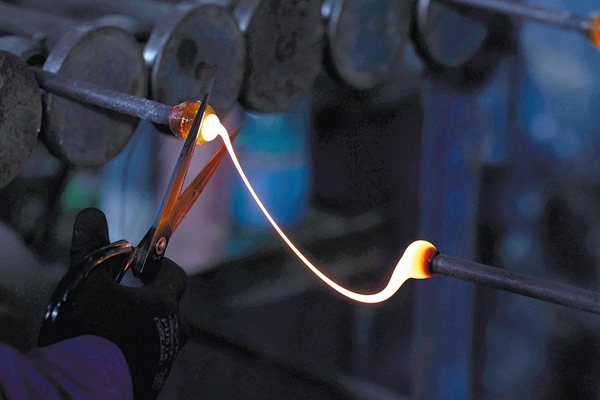

Workers prepare to pull molten glass at the factory. ZHU XINGXIN/CHINA DAILY

"Glass pulling tests not only one's eyesight and precise hand coordination but also the ability to endure high temperatures of the blowpipe," Luo said. "I often get burned by the hot blowpipe and have been injured multiple times."

Nowadays, Luo can complete over 300 stems in an hour. The glass-pulling process, a critical step in the ancient craft of handmade glassware, is challenging due to the need to control length, thickness and gloss.

For instance, when producing a wineglass stem, the length must be controlled within 1 to 2 millimeters, and the thickness within 0.5 mm. Luo can control the deviation to within 0.2 mm.

Wineglasses made by glassblowers in Qixian account for about 80 percent of the national production. Qixian is also the largest production and export base for handmade glassware in the country.

From raw materials to finished products, glassware undergoes more than a dozen processes, some requiring dozens of steps. The most difficult part of handmade wineglass production is the glass-pulling process. The biggest advantage of handmade glassware is its unique, delicate design, though it inevitably results in lower production volume and higher costs.

Molten glass goes through the pulling process at the factory. ZHU XINGXIN/CHINA DAILY

"Watching the red-hot molten glass pass from one worker to another and finally transform into crystal-clear glassware is like magic," Luo said. "I really enjoy the process, as each piece of glassware is born in my hands like artwork."

In 2000, after graduating from middle school, Luo joined the company as a delivery worker. She developed a strong interest in glassblowing and secretly practiced with leftover materials after work.

She said that even with two layers of gloves, the blowpipe was heavy and hot, causing her palms to blister over time. "Women's hands are usually delicate, but mine are covered with thick calluses," she said, showing her hands to a China Daily reporter.

The work of a glass smith is intense and technically demanding, so few women take on the role. Among the nearly 2,000 employees at her company, only about a dozen are glassblowers, and Luo is the only woman.

"When I work, I clear my mind of everything else and focus solely on glass pulling," Luo said.

In 2003, she achieved her dream of becoming a glassblower, which also brought her a better income. By then, she had mastered all the skills in the factory, including feeding materials, shaping molds, blowing and pulling glass. "After long hours of practice, I not only mastered the technique for pulling short glass stems of 100 mm but also the skills for pulling stems over 200 mm," Luo said.

Now, Luo can simply glance at a sample glass and touch it to know how much force to use to meet a customer's specifications.

In 2013, Luo won first place in the glass pulling category at the first glassware industry skills competition in Qixian. She has also received the National May 1 Labor Medal and the title of Qixian Glassware Artisan.

Two glassworkers blow molten glass through blowpipes at the factory. ZHU XINGXIN/CHINA DAILY

In 2018, as a front-line worker, Luo was elected as a representative of the Shanxi Provincial People's Congress.

"Being a representative is both an honor and a responsibility," she said.

During her tenure, Luo proposed suggestions on cultivating high-tech talent, rural development and the glassware industry's growth, based on her research and observations. "In addition to doing my job well, as a representative I must actively reflect the opinions and suggestions of the public," Luo said. "I always prioritize the interests of the people and strive to solve their problems."

Luo believes that regardless of the task, one must avoid speaking or acting without understanding the subject. This is the only way to live up to the heavy responsibilities on her shoulders, she said.

Chen Yuyu, head of the company's research and development department, said they are strengthening innovation to meet customers' high-quality lifestyle needs. Over 98 percent of the company's products are exported, with orders from Europe and the United States accounting for over 70 percent. Many of these products are crafted by Luo.

Qixian has nearly 60 glassware production enterprises, producing over 8,000 types of products, including tea sets, candleholders, vases and lamps, which are sold in more than 80 countries and regions.

Workers tidy up handmade wineglasses in the factory. ZHU XINGXIN/CHINA DAILY

However, Luo is still concerned about the future. "Looking at the current state of the glass industry, there are fewer young people in the factories," she said.

She's had many opportunities to move away from the front line, and the factory leaders had repeatedly offered her office management positions. "I feel that the furnace and the workshop are my stage," she said.

Luo expressed concern about the inheritance of the craft. The glassware manufacturing process has evolved over several generations, from simple daily-use glass to gifts, crafts and even art pieces.

Luo teaches Bakhrieva Takhmina, an international student from Shanxi University, how to blow glass through a blowpipe. ZHU XINGXIN/CHINA DAILY

Bakhrieva Takhmina, an international student from Shanxi University, is fascinated by glassware crafts. She was delighted to find Chinese ink paintings adorning glass salad bowls, reflecting innovative designs that blend Chinese and Western elements. Takhmina believes that glassware crafts need continuous inheritance and innovation to win the favor of consumers at home and abroad.

"I want to make our Chinese glassware products better through my efforts, so that more foreign friends will like our products," Luo said.

Wang Wendong contributed to this story.

Contact the writers at zhuxingxin@chinadaily.com.cn