Battery production fully charged by town's efforts

Updated: 2024-08-01

Shanxi province is home to dozens of characteristic towns with specialty industries and a number of these have achieved global reputations.

The townships of Zhangzhuang and Longchuan, located in Pingding county in the eastern Shanxi city of Yangquan, are two such places.

What connects the towns to the world is an industry chain that covers lithium-ion batteries and components.

Lithium-ion batteries are rechargeable batteries that use lithium ions as the primary component of their electrolyte. Nowadays, they are widely used in a range of products like electric vehicles, electric bikes and portable electronic devices such as smartphones, laptop computers and wearable devices.

Pingding is famous for the production of anode material for lithium-ion batteries. Local officials said that every one out of four new energy vehicles in the world is using anode material produced in the county.

An anode is the electrode in a polarized electrical device through which current flows in from an outside circuit. On the contrary, a cathode is the electrode in a polarized electrical device through which current flows out.

In a device that consumes electricity, like a rechargeable battery, the anode is the charged negative electrode.

In Pingding, a number of companies are using synthetic graphite to produce anode material and there are also quite a few enterprises engaged in the production of battery-related materials and components like cathode material, electrolyte and separators.

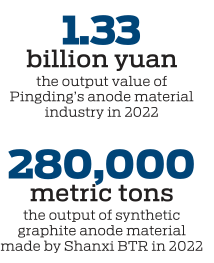

In 2022, Pingding's companies in the production of anode material realized a combined output worth 1.33 billion yuan ($183.54 million), growing 95.4 percent from the previous year, according to local statistics. The entire new-energy battery industry chain became the third-largest pillar sector in the county.

Leveraging local advantages in this industry, the authorities of Pingding county decided to develop a battery industrial town in the two townships of Zhangzhuang and Longchuan in 2021. The industrial town is now a part of the Pingding Economic and Technological Development Zone.

Over the past three years, the battery industrial town has witnessed booming development in investment attraction, construction and production.

A number of nationally leading companies in the new-energy battery industry, like Shanxi BTR, Beijing-based Zhongxuan Technology and Shanxi Zhongye New Energy Technologies, have invested in new facilities in the battery town.

Last year, Shanxi BTR's synthetic graphite facility, with an annual output of 12,000 metric tons, became operational in the Pingding. Other projects put into operation that year also included a special graphite facility invested in by Shanghai-based SGL Carbon Group, which is capable of producing 2,500 tons a year; and a Zhongye-funded lithium-ion battery anode material plant with an annual capacity of 40,000 tons.

Shanxi BTR, with its headquarters in Pingding county, is a nationally recognized high-tech enterprise engaged in the development and production of new-type carbon-based materials like synthetic graphite and anode material. It is vigorously expanding its business to meet rapidly growing demand in domestic and overseas markets.

And the production facilities in Pingding's battery town are a crucial part of its expansion, according to Zhang Shuai, deputy general manager and chief engineer of Shanxi BTR.

Following its synthetic graphite project, Shanxi BTR recently completed construction on a lithium-ion battery anode material plant with an annual output of 50,000 tons. Zhang said the plant's operation is expected to begin before the end of June.

He noted that this 50,000-ton plant is only the first phase of the project and its designed annual output will be 200,000 tons when the facility is fully completed. "This capacity will firmly consolidate our leading position in the world."

Shanxi BTR's total output of synthetic graphite anode material was 280,000 tons in 2022, ranking first worldwide. Last year, its global market share reached 22 percent.

Zhang said what gives the company an edge is its breakthroughs in graphitization – or graphite synthesis – technology.

"The phenomenon of graphitization furnace 'puffing' is an industry-wide challenge in graphite synthesis," Zhang said. "This can lead to uncontrollable product quality and even safety accidents."

Shanxi BTR has established a dedicated laboratory to tackle the problem. According to Zhang, the lab can simulate various scenarios of furnace puffing, helping researchers work out solutions to this problem.

"With this lab, the graphitization furnace puffing problem has been basically solved in Shanxi BTR," the executive said. "And our research results have been promoted throughout the industry nationwide."

The company has also established an advanced research and development center for carbon-based anode materials. While offering crucial support to the company's growth, the center is also providing solutions to assist Shanxi's new energy industry development as a whole, according to Zhang.

The successful development of companies like Shanxi BTR has put the Pingding battery town at the forefront of the domestic battery materials industry. In 2023, the battery town was recognized by Yangquan as a city-level characteristic town.

According to a local plan, the battery town will develop in three phases, with the first phase focusing on anode material production; the second phase extending to sectors like cathode materials, separators and electrolytes; and the third phase highlighting the production of complete sets of batteries.

Wang Qingwen contributed to this story.

Synthetic graphite developed in Pingding. CHINA DAILY

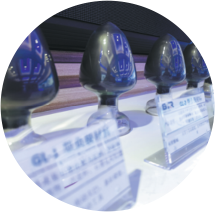

New anode material developed by Shanxi BTR. CHINA DAILY