Admixture a pillar of Wanrong's economy

Updated: 2023-03-17

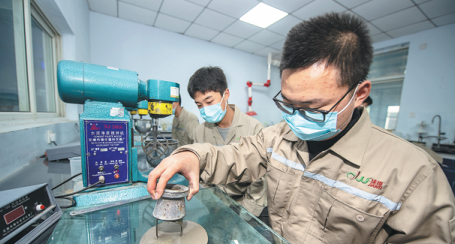

Technicians at a concrete admixture company in Wanrong county test products in a laboratory. [Photo by Xue Jun for China Daily]

While the building industry in China has experienced rapid growth over the past decades, few people realize that concrete admixture is a crucial part of this industry.

The admixture, or additive agents in various forms, is used to closely bind cement, sand and gravel together to improve the performance of concrete in erosion resistance, heat insulation and strength.

But for one county in North China's Shanxi province, concrete admixture is known to almost everyone. The niche product has developed into a local economic pillar, offering jobs to tens of thousands of residents.

The Shanxi provincial government released its first batch of 10 provincial-level characteristic towns and the county of Wanrong was on the list thanks to the product.

Developing towns with characteristic industries is a new strategy in Shanxi, which aims to create advantageous industries for local growth.

Wanrong's history in this industry dates back to about 40 years ago. Starting from several small mills producing the additive with primitive equipment and techniques, the industry has evolved into a crucial local industry with a total output value accounting for about one-third of the total for the Chinese market.

The county is now home to 65 concrete admixture producers. They produce more than 1 million metric tons of product varieties a year, with a combined output value of more than 4 billion yuan ($580.8 million).

More than 80,000 Wanrong residents are engaged in the industry, working with local manufacturers or doing sales throughout the country.

One of the concrete admixture research and development facilities in Wanrong. [Photo by Yan Xin for China Daily]

Wang Fei, mayor of Wanrong, said local producers are proud that their products have been used for many landmark projects in the country, including the Three Gorges Dam and the Qinghai-Tibet Railway. The products have also reached more than 30 countries and regions.

The official found that a priority on innovation and developing products to meet the diversified demands of clients are among major factors contributing to the industry's growth.

He noted that local enterprises have collaborated closely with renowned research institutions in the country to enhance their competence in research and development.

With the help of the institutions, there are 18 corporate technological centers and other R&D facilities in Wanrong. In addition, there are 15 local companies recognized as high-tech enterprises.

Zhang Zhimin, chairman of local manufacturer Aoruite, said he is a witness to the industry's growth, especially its increasing strength in technological competence.

"About 40 years ago, we used washbasins to produce the additives," Zhang said. "Now, advanced reactors are standard to every producer."

The executive added that local manufacturers are beginning to diversify to segmented markets and are targeting their R&D to meet the diversified demands of clients.

"Our researchers have traveled extensively in the country and the world to study how to develop products to suit regional requirements," Zhang said. "We investigate the differences of cement, sand and gravel in various regions and develop suitable products through numerous analyses, experiments, tests and trials."

County Mayor Wang said he is more optimistic about the industry's future after Wanrong made the list of characteristic towns.

He said the listing will offer an unprecedented opportunity for the industry by accelerating the formation of an industrial cluster and helping to increase the influence and recognition of local products in both domestic and international markets.

Wanrong aims for the concrete admixture industry to have more than 100 manufacturers and an annual output value of 10 billion yuan by 2025.

Zhang Haiying contributed to this story.